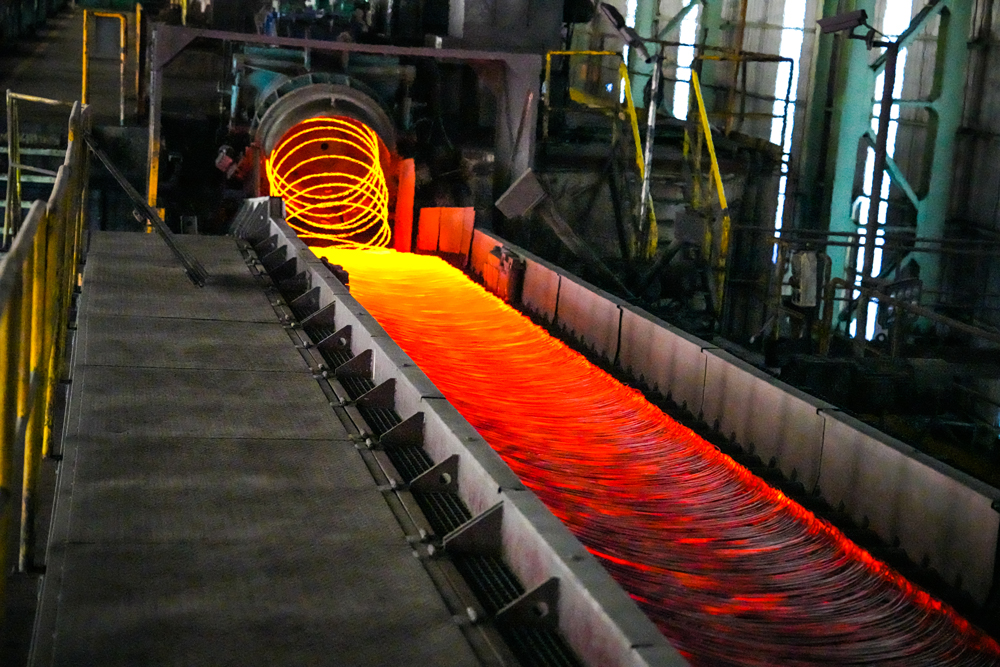

Rolling Mill

Rolling mills are the last stop of an iron and steel plant on the road from raw material to final product. In our Tosyalı Algerie iron and steel complex, we operate with five rolling mills with a total capacity of 7.2 million tonnes per year.

- Wire Rod Mill: 0.5 Million Tonnes

- Rebar Mills: 2.7 Million Tonnes

- Hot Rolled Coil Mill: 4 Million Tonnes

To give the billets the desired shape, they are cooled with water during the rolling process. Thus, the hot billets coming from the Continuous Casting Machine (CCM) begin to solidify.

Afterwards, the billets are transformed into rebars and wire rods by horizontal and vertical rolling.

Following the cooling process, the rebar bundles and wire rod coils, each weighing 2 tonnes, are labeled. The digital labeling system, which includes all details about the product, ensures that the products can be easily recognized and monitored by customers.

Finally, the products are transported to the warehouse area using magnetic ceiling cranes to ensure they are not physically damaged before being sent to customers.

Hot rolled coils are produced by hot rolling of slabs in the mill. Within the facility, coils down to 1 mm thickness and up to 1600 mm width can be produced.