Spiral steel pipes from Tosyalı Algerie are produced according to the ISO 14001 and ISO 45001 standards.

The Spiral Steel Pipe Unit produces spiral welded steel pipes, adhering to internationally recognized standards such as the following:

- API

- API Q1 ISO

- EN

- DIN

- NFA

- AWWA

- BS

and other well-known international standards. It is capable of both bare pipe production and coating-lining applications.

Our production efficiency has been homologated and certified by all international accreditation associations. The Spiral Steel Pipe Unit is also verified by third-party inspection agencies through periodic audits.

According to the project requirements, our Unit may supply pipes for any kind of domestic and international project.

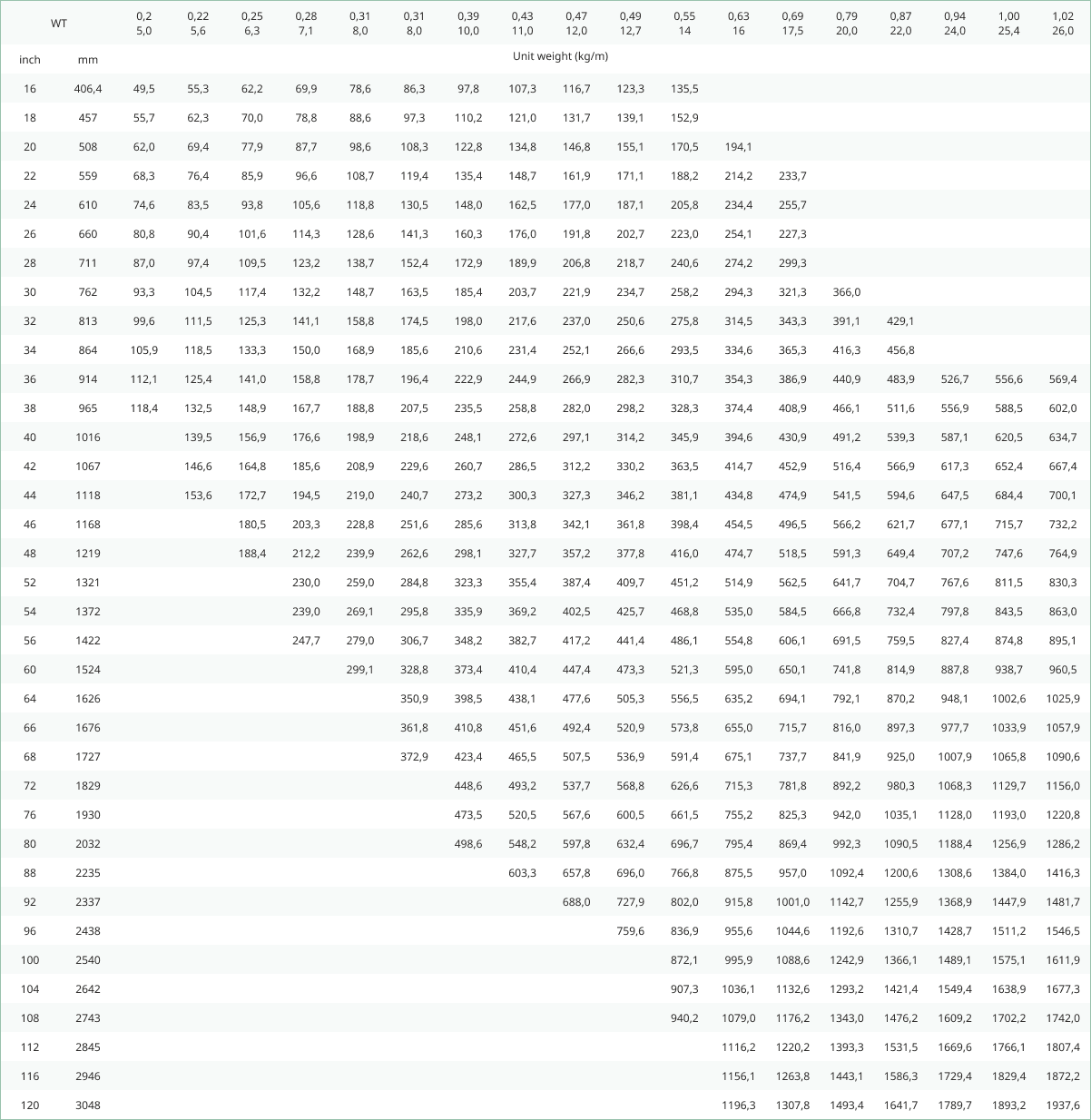

Spiral steel pipes production options and range

-

Diameter

16 – 120 inch (406,4 – 3.048 mm)

-

Wall Thickness

0,2 – 1,02 inch (5 – 26 mm)

| Pipe production | |

|---|---|

| API Spec 5L PSL1 and PSL2 | EN10217 |

| ISO 3183 | EN 10219 |

| CZA Z 245.1 | ASTM A252 |

| EN 10224 | AWWA C2000 |

| External coating | |

| Polyethylene Coating | EN ISO 21809, DIN 30670, NFA 49-710, UNI 9099 |

| Polypropylene Coating | EN ISO 21809, DIN 30678, NFA 49-711 |

| Single/Double Layer FBE (Fusion Bonded Epoxy) Coating | CZA Z 245-20, NACE RP 0394, API 5L7, AWWA C213 |

| Liquid Epoxy Applications | AWWA C210, NFA 49-709, EN 10289 |

| Polyurethane Coating | BS 5493, EN 10290, AWWA C222 |

| Internal Lining | |

| Epoxy Lining | API RP 5L2, AWWA C210, NFA 49-709, EN 10339, EN 10301 |

| Polyurethane Lining | AWWA C222 |

-

Diameter

Pipes are manufactured in diameters ranging from 16 to 120 inches.

-

Wall Thickness

Our pipes vary in thickness, ranging from 0.2 inches (5 mm) to 1.02 inches (26 mm).

-

Production Standards

Depending on the project, our steel pipes are produced in accordance with national and international production standards.

-

Tests

Tosyalı Algeria conducts thorough testing, inspection, and confirmation of product conformity at every production stage, aligning with standards and project specifications.

-

Coating & Lining

Pipes are coated with different materials according to the customer's usage and demand.

-

Marking

The robotic online pipe monitoring system utilizes external and internal markings to ensure convenient and dependable pipe identification.

- Product Catalogue 2025 (PDF)

Gallery

Contact

Leave us a message

-

Pôle Economique Plateau Gourirate commune Béthioua wilaya d’Oran Algérie+213 41 793132+213 41 793132